XTREME GRIND TS

XTREME GRIND TS outperformed the competition and delivered a cost savings of up to 50%. Our GTL grinding oil runs exceptionally clean, making it well-suited for this manufacturer’s 22 Transor one-micron filtration systems.

The Challenge

This custom tool manufacturer is a member of a global industrial group. Their 60,000 square foot manufacturing facility, located in upstate South Carolina, provides engineered cutting tool solutions primarily for the automotive and aerospace industries.

To keep their grinding oils running clean, they use Transor Filtration Systems, which are industry-leading filtration systems for tool and cutter grinding. These systems provide one-micron filtration, which allows for tighter tolerances, lower maintenance costs, and faster time cycles. The manufacturer invested in 22 Transor systems, with a total capacity of 9,000 gallons, to feed their 40+ grinders with exceptionally clean oil.

To select the best grinding oil for their needs, they tested three synthetic grinding oils: QualiChem XTREME GRIND TS, a gas-to-liquid base grinding oil, and two different competitors’ hydrocrack base grinding oils. QualiChem XTREME GRIND TS outperformed the competition, offering a 50% cost savings over one and a 20% cost savings over the other.

The Solution

XTREME GRIND TS

Premium Series Gas-to-Liquid Grinding

XTREME GRIND TS is an ultra-low viscosity grinding fluid designed primarily for tool and cutter grinding applications. Its excellent wetting properties and low viscosity keep the grinding zone clean of debris. Made from exceptionally clean gas-to-liquid (GTL) synthetic oils, XTREME GRIND TS meets the specifications for one-micron filtration systems, and does not contain additives such as fat, sulfur, chlorine, or phosphorous which can interfere with the filtration process.

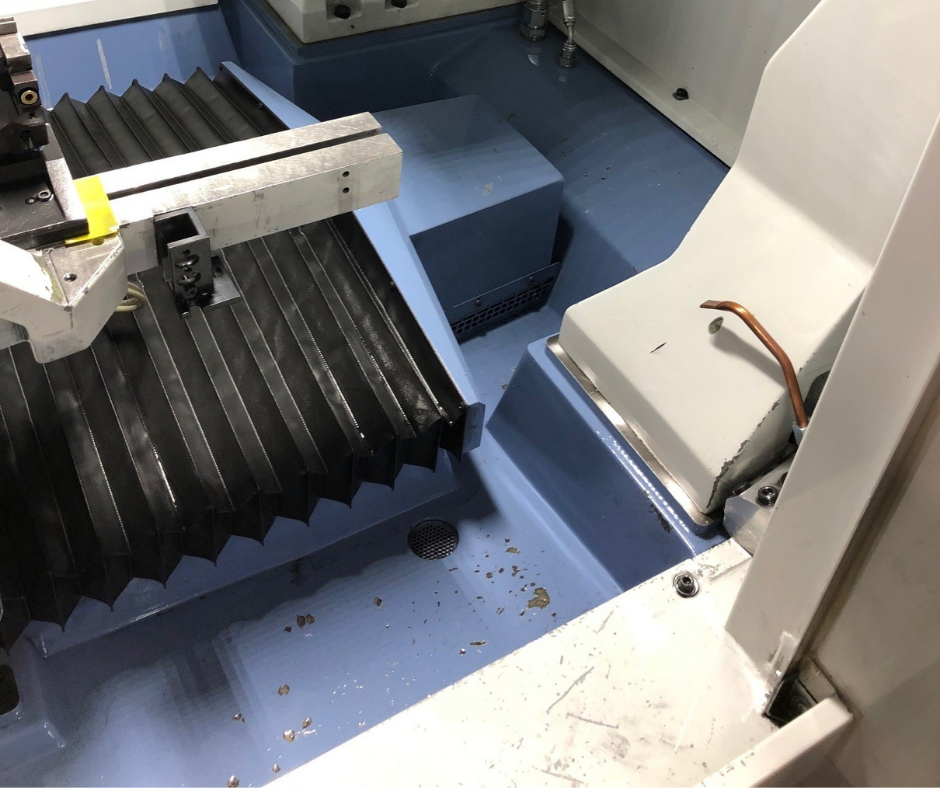

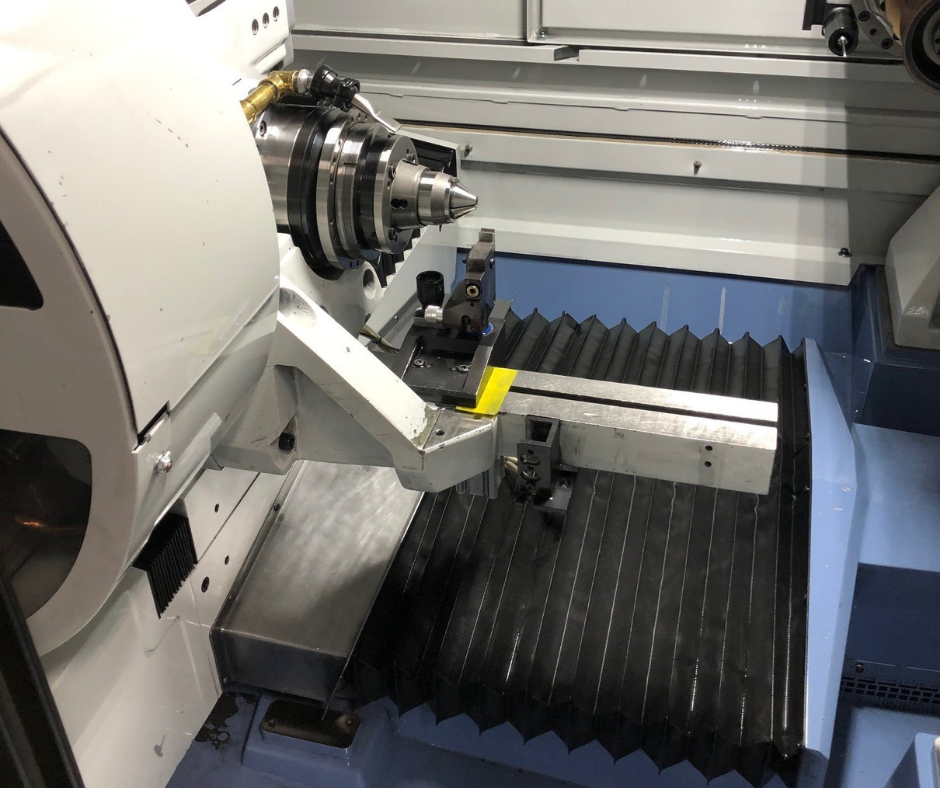

Above is one of the grinder cabinets after running XTREME GRIND TS for 3 months. The cleanliness of the machine ensures that the grinder operates at peak performance in terms of accuracy and reliability.

Process and Equipment

Machines

ANCA, WALTER & REINECKER multiple-axis tool grinding machines

Materials

Carbide containing 6-10% cobalt

Competitor Products

Hydrocrack base cutting oils

Operations

Grinding with diamond wheels

The Trial

The manufacturer tested 3 grinding oils: QualiChem XTREME GRIND TS, a gas-to-liquid base grinding oil, and two different competitors’ hydrocrack base grinding oils. XTREME GRIND TS outperformed the competition, making it the manufacturer’s grinding oil of choice.

Cost Savings

A 50% cost savings over one and a 20% cost savings over the other

Usage Rate

Reduced usage by 5% to 10%

Filtration Performance

The Transor systems ran at lower temperatures and collected more of the grinding swarf

Machine Cleanliness

There was significantly less carbide sludge in the machines and in the clean tanks of the Transor systems

Odor & Mist

Odorless and low misting

The Results

Running XTREME GRIND TS, the following benefits were realized:

- Better overall performance for less money

- Reduced usage

- Their Transor filtration systems ran at lower temperatures, and ran more efficiently

- High operator acceptance

- No odor and less misting